Anatoly A. Tokarev, Russia, 2007

That was got as a result:

4 channels of the regulation;

the regulation of the output voltage from 0 before

practically 12 In

stair, 128 stairs of the regulation;

the regulator is executed on scheme SEW so in it

nothing do not get-warm (at least once so that there was it is necessary to put

the radiators);

the frequency SEW 31250 Hz - an ultrasonic range - so

works noiseless, no snub ;

after enabling rheobas (the computer) for 10 seconds

occurs spinup ventilator on maximum voltage (12 volts), simultaneously occurs observation

maximum velocity of the rotation impeller ventilator;

after spinup voltage in channel is fixed such, what it

was under the last regulation and rheobas moves over to operating duty;

the speed measurements of the rotation impeller

ventilator occurs round-robin, in 2 seconds is chosen next channel, is measured

velocity, results of the measurement are removed on screen in the manner of

absolute importance (in rotation per minute) and in the manner of percent from

maximum velocity;

if the impeller cost(stand)s (no tahoe a signal), is

removed report on damages on indicator and is given bleep (the amount

"cheep" corresponds to the number of the channel, in which has

occurred the damage);

the channel possible to switch off, bring level of the

output voltage before 0, herewith it will not be interviewed, but on screen is

removed message "out-of-work".

As it is seen, scheme became greatly in contrast with

previous variant more simply. Do Not think that one more alteration will allow

to do rheobas in 2 resistors :).

Some explanations to scheme:

the microcontroller DD1 forms 4 SEW the signal for

governing P-canal MOSFET key DA1, DA2;

for clock microcontroller is used internal generator 8

MHZ, this has allowed to free the vapour a conclusion (for possible hereinafter

connections sensor temperature) and reduce the price of the scheme;

information about the work channel regulations is

removed on two-row ZHK indicator HL1, information in indicator is sent on quad

bit to bus;

the buttons S1-S3 control work of rheobas, capacitors

S2-S4, included parallel button, are intended for suppression bounce, are used

internal tightening resistors on conclusion of the microcontroller, to which is

connected buttons;

the chain R9,C5 and internal tightening resistor of

the microcontroller execute the function of the voltage level co-ordination

and, simultaneously, function of the filter of the low frequency, suppressing

to a certain degree short pulsed hindrances in tahoe a signal ventilator;

for relief of searching for radio elements, the

co-ordination level voltages of the microcontroller and MOSFET of keys are

executed otherwise, than in previous scheme: instead of microcircuit of the

co-ordination level 74F07, is used other scheme of the feeding (the stabilizer

of the negative voltage DA3) with the result that findings Vcc microcontroller

and Vdd indicator are connected to voltage +12 В, but findings GND microcontroller and Vss indicator

are connected to voltage +7 In

(leaving the stabilizer DA3). The Voltages are brought to the general wire (the

body) of the computer feeding.

Such decision aside from plus (the stabilizer 79L05 to

find greatly more simply, than 74F07), has and negative side: printed charge

and particularly indicator it is necessary to fix so that was not a contact no

their current-carrying parts (the conductor, platform, frames of the indicator

etc.) with body of the computer!

Management:

S1 - "less", reduces the voltage on

ventilator;

S2 - "fix", fixes the current channel,

triangle appears left of inscription "Channel", the repeated striking

removes fixing the channel, they will newly be switched in 2 seconds;

S3 - "more", enlarges the voltage on

ventilator.

simultaneous striking S1+S3 - an unset rheobas, is

newly produced spinup of impeller and measurement to maximum velocity of the

rotation.

Long striking on button (long 1 seconds) includes auto

cycling.

Now about

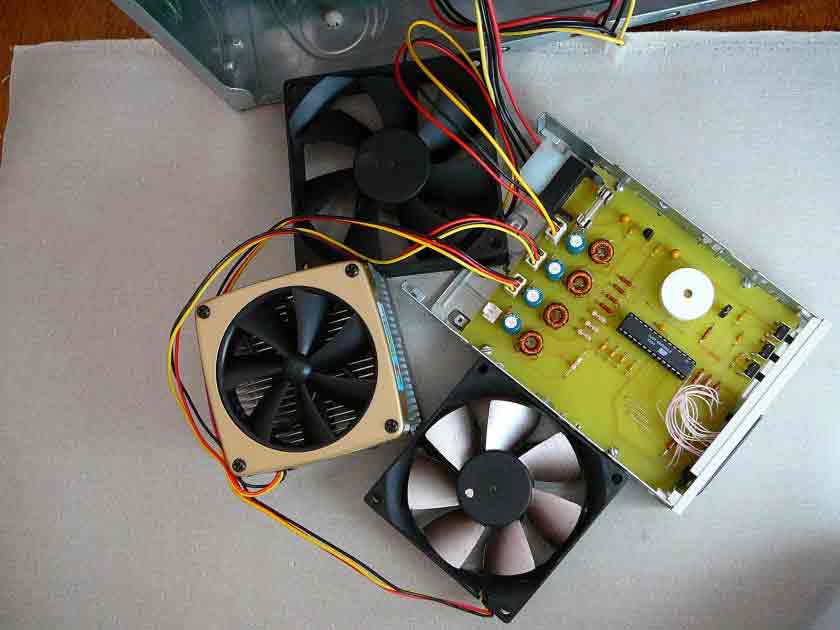

designs: this variant, either as

previous rheobas, am going to to place in compartment 3,5" so as constructive

I have taken the old spindle 3,5", has thrown whole stuffing, has sawed;

sawn off the spare glandules and from face plastic panel has left only frame:

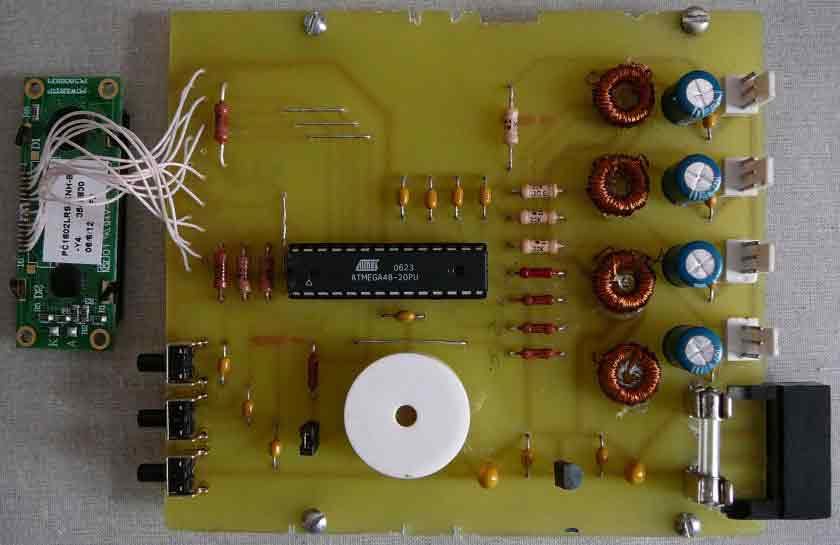

We Assemble the elements (DA1, DA2 - on the part of

conductor!), throttles L1-L4 crepe on charge hot melt, solder the indicator.

On charge, beside connector of the connection of the

feeding, is installed fusible fuze in chain of the general wire ventilator,it,

certainly, possible change the jumper, however better his(its) put(deliver) to

under casual closing conclusion 1,2

in connector XP1-XP4 not to burn the keys DA1, DA2. I

was lazy immediately its put(deliver), as a result happened to to change the

burned; burned microcircuit DA2.

For fastening the charge 4 screws M3 we use to constructive,

it is necessary to take not too long - that they did not protrude from below -

and, in ditto time that their lengths have been enough for installing plastic little

buildings, raising slightly charge from constructive. This will allow align

position of the buttons by the vertical.

The Indicator while (for time first experiment) shall

bolt hot glue.

Programming the microcontroller:

Categorically it is impossible programmer the

microcontroller, stated in board of

rheobas and eating from this computer - possible all пожечь!

Without fall programmer the microcontroller or in

industrial programmator, or if it homemade and is intended for in-circuit of the

programming, connect to it panel for

installing the microcircuit.

The Regulation:

Single that can require the regulations, this

adjustment contrast scenes on indicator. For regulation change the chain a

resistor R3, R4 on variable (preset) resistor 10 lumps, extreme findings of the

variable resistor connect to chain +12 В and +7 В, but average output (the crawler) to

output 3 indicators. Approaching scenes, on indicator. Unsolder resistor from

board. To make size, resistances shoulder variable resistor (from average

output before extreme outled) and install the constant resistors such or close

nominal value.

No more regulations rheobas require.

We Proceed with experiment.

We Connect the ventilators and feeding, in channel 4

ventilators do not include:

After enabling (or after simultaneous striking the

buttons S1, S2), during of the spinup.

Indication of

velocities in channel in rotation per minute and percent from maximum

velocity.

In channel 4

ventilators was not connected so signal is removed about damages.

The Channel

possible to switch off, for this it is necessary to reduce the voltage before

0.

As a matter of

convenience regulations, channel, in which goes the regulation possible to fix

striking the button S2 If install too small voltage on ventilator, tahoe a

sensor can give the wrong signal, as a result of evidences speed will be

distant from reality.

The Practical advice: undesirable to install the

velocity of the rotation below 30% from maximum, many ventilators in this case

give the sloppy tahoe a signal.

Remained invent form and highly of the buttons, neatly

do the front panel from stub. But this I will concern this at May.

For interesting persons to repeat rheobas, are

enclosed:

the drawing of the printed board (ready to use on

lazer-ironing to technologies);

the picture with location element on printed board;

the lace trim of the microcontroller;

the primaries. Schematic:

Constrution examples:

Source code:

'===============================================================================

'

' 4 channel PWM rheobus for computer's fans on ATMega48.

'

' Rheo200Le.bas

'

' (c) Anatoly A. Tokarev 2007, atlab@zmail.ru

' NOT FOR COMMERCIAL USE!

'

' This is my first project on Atmel's microcontroller.

' It was started on 26 march 2007 and was fully (with hardware

' making and debugging) completed on 19 april 2007

' THANKS TO THE BASCOM-AVR.

'

'===============================================================================

'

' Design features:

' - internal ATMega RC generator 8 MHz

' - 4 PWM channels (regulation and measurement)

' - PWM is in ultrasound range (no sounds or clicks)

' - 0V <= Vout <= 12 V

' - 3 button user control

' - 2*16 LCD (# channel, fan speed: rpm and percentage of max speed)

' - 10 sec. full speed spinup after power on

'===============================================================================

'

'-- Control --------------------------------------------------------------------

' - button "Right" - increase fan speed

' - button "Left" - decrease fan speed

' - button "Center" - select # fan

' - buttons "Left+Right" - soft reset

'

'-- LCD ------------------------------------------------------------------------

' Db4 - PortC.0

' Db5 - PortC.1

' Db6 - PortC.2

' Db7 - PortC.3

' E - PortC.4

' Rs - PortC.5

'

'-- PWM outputs ----------------------------------------------------------------

' 5 - OC2B/PD3 - Pwm4

' 11 - OC0B/PD5 - Pwm2

' 12 - OC0A/PD6 - Pwm1

' 17 - OC2A/PB3 - Pwm3

'

'-- FAN tach -------------------------------------------------------------------

' 15 - PortB.1 - Tach1

' 16 - PortB.2 - Tach2

' 18 - PortB.4 - Tach3

' 19 - PortB.5 - Tach4

'

'-- Buttons --------------------------------------------------------------------

' Left (Key1) - PinD.0

' Center (Key2) - PinD.1

' Right (Key3) - PinD.2

'===============================================================================

$regfile = "m48def.dat"

$crystal = 8000000

'-- Timers init ----------------------------------------------------------------

'TMR0 and TMR2 use FAST PWM mode

Tccr0a = &HF3

Tccr0b = &H01

Tccr2a = &HF3

Tccr2b = &H01

' TMR1 used for fan failure check

Config Timer1 = Timer , Prescale = 64

'-- Ports init -----------------------------------------------------------------

Config Portb = &B11001001 'PB1,2,4,5 outputs, other - inputs

Portb = &B00110110 'use pullup on inputs

Config Portc = &B10111111 'PŃ6 - input

Portc = &B01000000 'use pullup on inputs

Config Portd = &B11101000 'PD0,1,2,4 - inputs

Portd = &B00010111 'use pullup on inputs

'-- LCD config ------------------------------------------------------------------

Config Lcdpin = Pin , Db4 = Portc.0 , Db5 = Portc.1 , Db6 = Portc.2 , Db7 = Portc.3 , E = Portc.5 , Rs = Portc.4

Config Lcd = 16 * 2

'-- Buttons config -------------------------------------------------------------

Key1 Alias Pind.0 ' âëĺâî

Key2 Alias Pind.1 ' öĺíňđ

Key3 Alias Pind.2 ' âďđŕâî

'-- Alarm zummer ---------------------------------------------------------------

Speaker Alias Portd.4 '

'-- Variables ------------------------------------------------------------------

Dim T1over As Bit ' flag, if Timer1 is overflowed, whis is fan failure

Dim Needshow As Bit ' flag, need to show rpm

Dim Needtosave As Bit ' flag, need to save data in EEPROM

Dim Fixnchan As Bit ' flag, # channel is fixed

Dim Key1pressed As Byte '

Dim Key2pressed As Bit '

Dim Key3pressed As Byte '

Dim Cntr As Byte ' counter

Dim Ptr As Byte ' pinter

Dim Q(4) As Byte ' relative pulse duration

Dim Nchan As Byte ' # selected channel

Dim Nc As Byte

Dim Pcintcntr As Byte ' counter for 1/2 revolution

Dim Perc As Word '

Dim I As Byte '

Dim J As Byte '

Dim K As Byte '

Dim Pixelprogress As Word

Dim T1 As Word ' TMR1 save buffer

Dim Nmax(4) As Word '

Dim N(4) As Word '

Dim Nl As Long ' speed, rpm

Dim Buf As Word

Dim W As Word

Dim Nchstr As String * 1

$eeprom ' preprogrammed speed

Data 32 , 64 , 128 , 196

$data

'-- Interrupts -----------------------------------------------------------------

On Pcint0 Isr_pcint0 ' PortB pin change interrupt (from fans)

On Ovf1 Isr_tmr1 '

'-- Begin ----------------------------------------------------------------------

Progstart: ' soft reset label

Pcmsk0 = 0 '

Timsk = 1 '

Disable Pcint0

Stop Timer1

Disable Timer1

Pwm0a = 255

Pwm0b = 255

Pwm2a = 255

Pwm2b = 255

'-- User defined symbols in LCD ------------------------------------------------

'-- Progressbar ----------------------------------------------------------------

Deflcdchar 0 , 32 , 32 , 32 , 32 , 32 , 32 , 32 , 32 '

Deflcdchar 1 , 16 , 16 , 16 , 16 , 16 , 16 , 16 , 16 '

Deflcdchar 2 , 24 , 24 , 24 , 24 , 24 , 24 , 24 , 24 '

Deflcdchar 3 , 28 , 28 , 28 , 28 , 28 , 28 , 28 , 28 '

Deflcdchar 4 , 30 , 30 , 30 , 30 , 30 , 30 , 30 , 30 '

Deflcdchar 5 , 31 , 31 , 31 , 31 , 31 , 31 , 31 , 31 '

'-- Right triange --------------------------------------------------------------

Deflcdchar 6 , 16 , 24 , 28 , 30 , 30 , 28 , 24 , 16 '>

Cls

Cursor Off Noblink

Upperline

Lcd "Rheobus v2.00Le "

Lowerline

Lcd "(c) 2007 ATLab "

Waitms 10000 ' 10 sec. spinup

Needshow = 0

Enable Interrupts

For Nchan = 1 To 4 Step 1 ' read PWM presets

Ptr = Nchan + 8

Readeeprom Q(nchan) , Ptr

Gosub Speedmeter ' Max speed measurment

Waitms 500

If Needshow = 1 Then

Gosub Calcspeed

Nmax(nchan) = Nl '7500000 T1

Needshow = 0

Else

Nmax(nchan) = 0

End If

Next Nchan

Pwm0b = Q(1) ' set PWM

Pwm0a = Q(2)

Pwm2a = Q(3)

Pwm2b = Q(4)

Waitms 2000 ' 2 sec. for spin stabilization

Nchan = 4

Cntr = 3

T1over = 0

Needshow = 0

Needtosave = 0

Fixnchan = 0

Key1pressed = 0

Key2pressed = 0

Key3pressed = 0

'-- Endless loop ---------------------------------------------------------------

Do

' buttons 1,3 check pressed

If Key1 = 0 Or Key3 = 0 Then

' 1,3 pressed simultaneously

If Key1 = 0 And Key3 = 0 Then

Goto Progstart ' soft reset

End If

' if pressed 3 (Right), increase rpm

If Key3 = 0 Then '

If Key3pressed < 5 Then '

Key3pressed = Key3pressed + 1 ' autorepeat after 1 sec

End If

If Key3pressed = 1 Or Key3pressed => 5 Then ' first press and autorepeat

If Q(nchan) => 254 Then

Q(nchan) = 255

Else

Q(nchan) = Q(nchan) + 2

End If

End If

Else

Key3pressed = 0 ' flag clear if button isn't pressed

End If

' if pressed 1 (Left), decrease rpm

If Key1 = 0 Then '

If Key1pressed < 5 Then '

Key1pressed = Key1pressed + 1 ' autorepeat after 1 sec

End If

If Key1pressed = 1 Or Key1pressed => 5 Then ' first press and autorepeat

If Q(nchan) <= 2 Then

Q(nchan) = 0

Else

Q(nchan) = Q(nchan) - 2

End If

End If

Else

Key1pressed = 0

End If

' setup PWM

Pwm0b = Q(1)

Pwm0a = Q(2)

Pwm2a = Q(3)

Pwm2b = Q(4)

Cntr = 0

Needtosave = 1

' RPM measurement after speed change

If Q(nchan) = 0 Then

Gosub Showfan

Else

Gosub Speedmeter '

End If

Else

Key1pressed = 0

Key3pressed = 0

End If

' check button 2 (center) pressed

If Key2 = 0 Then ' select (fix) cahnnel

If Key2pressed = 0 Then

Key2pressed = 1

Locate 1 , 1

If Fixnchan = 0 Then

Fixnchan = 1

Lcd Chr(6) ' >

Else

Fixnchan = 0

Lcd " "

End If

End If

Else

Key2pressed = 0

End If

' pause 0.25 sec for the process sync.

Waitms 250

Cntr = Cntr + 1

' 0.5 sec later button release: save PWM data in EEPROM

If Needtosave = 1 Then

If Cntr => 2 Then

Writeeeprom Q(1) , 9

Writeeeprom Q(2) , 10

Writeeeprom Q(3) , 11

Writeeeprom Q(4) , 12

Needtosave = 0 '

End If

End If

' next channel measerement after 2 sec.

If Cntr => 8 Then '

Cntr = 0

If Fixnchan = 0 Then

Nchan = Nchan + 1 ' select next channel:

If Nchan > 4 Then ' 1->2->3->4->1..

Nchan = 1 '

End If

End If

If Q(nchan) = 0 Then

Gosub Showfan

Else

Gosub Speedmeter ' measurement

End If

End If

If Needshow = 1 Then ' Measurement executed

Gosub Calcspeed ' Calculate the rpm

N(nchan) = Nl '

If N(nchan) > Nmax(nchan) Then

Nmax(nchan) = N(nchan)

End If

Gosub Showfan ' and show on LCD

Needshow = 0

End If

' time is over, this is fan failure

If T1over = 1 Then

Gosub Showfan ' show on LCD

T1over = 0

End If

Loop

'-------------------------------------------------------------------------------

'===============================================================================

' Show results on LCD

Showfan:

'-------------------------------------------------------------------------------

Nc = Nchan + 48 ' for ROM economy

Nchstr = Chr(nc) '

Cls

Locate 1 , 1

If Fixnchan = 1 Then

Lcd Chr(6) '"{201}" (like ">" sign)

Else

Lcd " "

End If

Locate 1 , 2

Lcd "Channel" ' channel

Lcd Nchstr ' number

If Q(nchan) = 0 Then

Lcd " is OFF " '

Else

If T1over = 1 Then

Lcd " ALARM! " '

For I = 1 To Nchan ' make sound

For W = 600 To 300 Step -4

Sound Speaker , 5 , W '

Next J

Waitms 200

Next I

Else

Lcd " "

Lcd Str(n(nchan)) ' RPM

Lcd " rpm" '

Perc = N(nchan) * 10 ' calc percentage of Max Speed

Pixelprogress = Perc

Buf = Nmax(nchan) 10

Perc = Perc Buf

Locate 2 , 2 ' show %

Lcd Str(perc)

Lcd "% "

Buf = Nmax(nchan) 5

Pixelprogress = Pixelprogress Buf ' Nmax(nchan)

Locate 2 , 6 ' show progress bar

For I = 0 To 9 Step 1

J = I * 5

K = J + 5

If K > Pixelprogress Then

If J > Pixelprogress Then

Ptr = 0

Else

Ptr = Pixelprogress Mod 5

End If

Else

Ptr = 5

End If

Lcd Chr(ptr)

Next I

End If

End If

Return

'===============================================================================

'===============================================================================

' Speed calculation

Calcspeed:

'-------------------------------------------------------------------------------

Nl = 7500000 T1

Return

'===============================================================================

'===============================================================================

' Speed measurement start

Speedmeter:

'-------------------------------------------------------------------------------

If Q(nchan) = 0 Then ' if channel is Off, no measure

Return

End If

Pcintcntr = 0

Timer1 = 0

T1 = 0

Start Timer1

Select Case Nchan '

Case 4

Pcmsk0 = &B00100000 ' interrupt mask for Tach4

Case 3

Pcmsk0 = &B00010000 ' interrupt mask for Tach3

Case 2

Pcmsk0 = &B00000100 ' interrupt mask for Tach2

Case 1

Pcmsk0 = &B00000010 ' interrupt mask for Tach1

End Select

Waitus 5 '

Pcifr = 0 ' clr flag

Enable Pcint0 ' enable interrupts

Enable Ovf1 '

Return

'===============================================================================

'===============================================================================

Isr_pcint0:

'-------------------------------------------------------------------------------

If Pcintcntr = 0 Then

Timer1 = 0 ' start revolution time measurement

End If

Pcintcntr = Pcintcntr + 1

If Pcintcntr = 5 Then

Stop Timer1 ' stop measurement

T1 = Timer1

Pcmsk0 = 0 ' clr all tach masks

Disable Pcint0 '

Disable Timer1 '

Needshow = 1

'

End If

Return

'===============================================================================

'===============================================================================

Isr_tmr1:

'-------------------------------------------------------------------------------

Stop Timer1

Disable Timer1

T1over = 1 ' set overflow flag

Return

'===============================================================================

End |